PRONORTEC nanotechnology: an alternative to traditional phosphatation

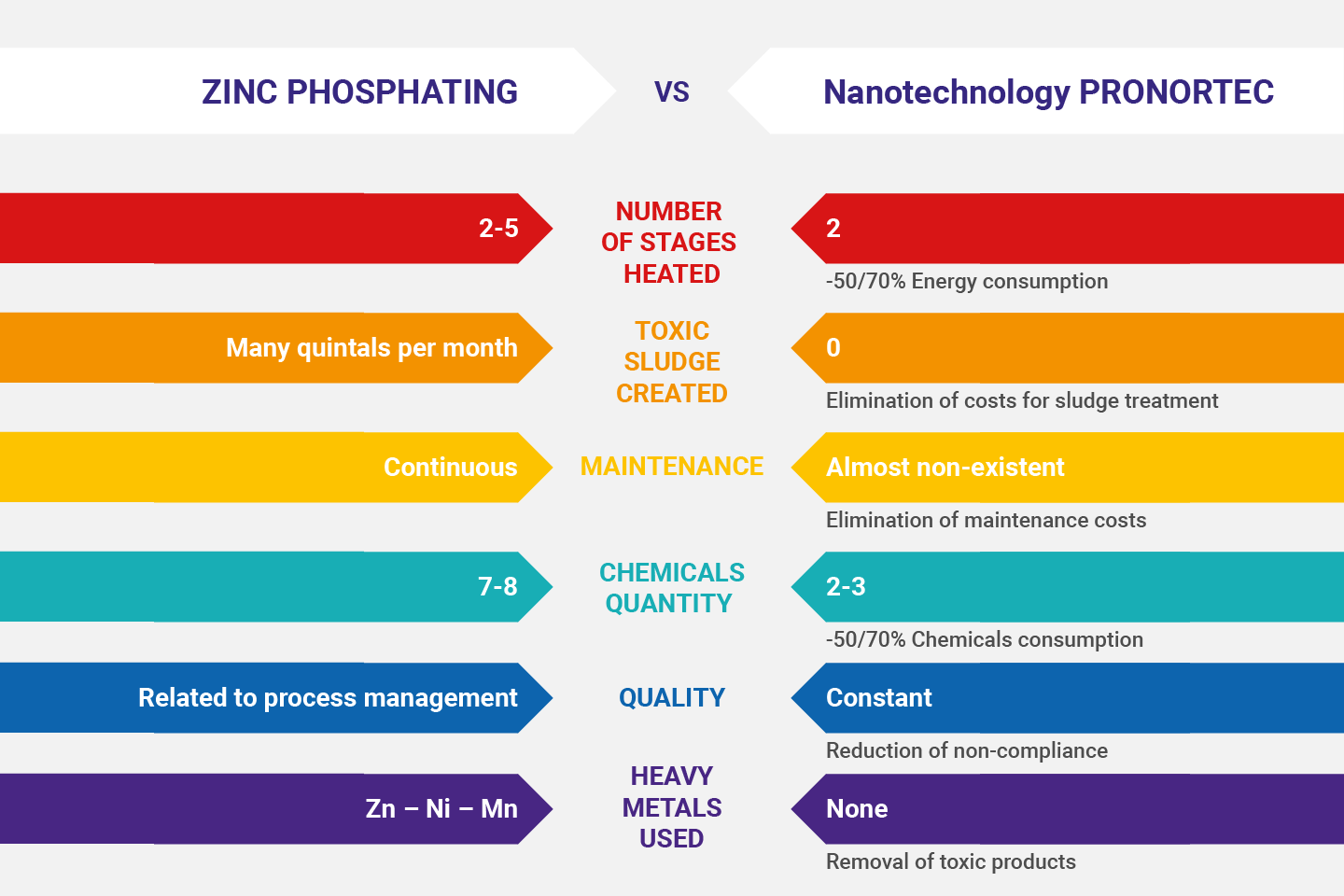

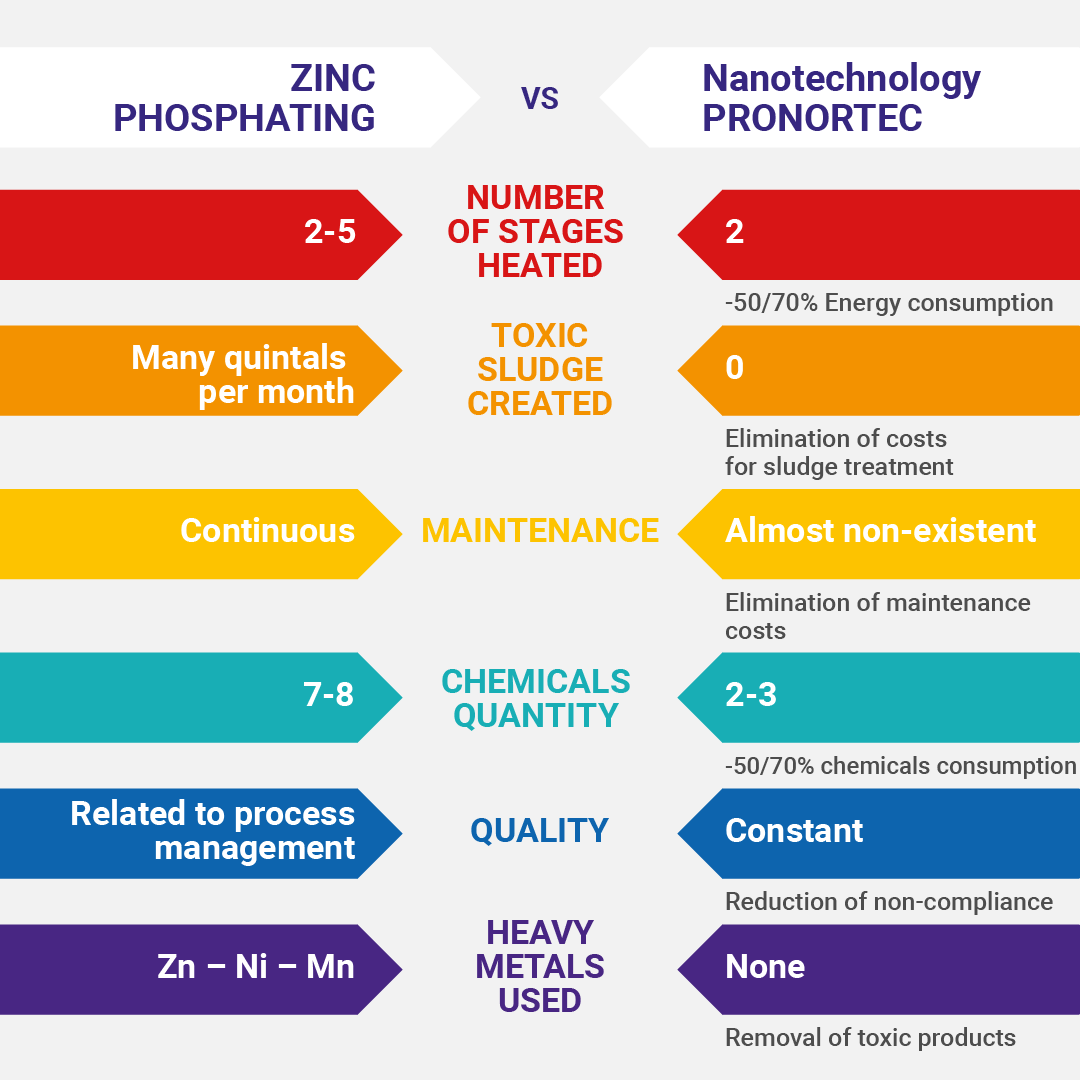

PRONORTEC nanotechnology is an eco-friendly and cost-effective alternative to traditional tricationic/microcrystalline phosphatation

PRONORTEC nanotechnology is an eco-friendly and cost-effective alternative to traditional tricationic/microcrystalline phosphatation like zinc phosphating.

This innovative chemical process for metal surface pretreatment, based on organic phosphorus compounds, creates a highly hydrophobic and adhesive nanocoating.

Thanks to its nanometric structure, PRONORTEC line products offer higher performance in terms of corrosion resistance and paint adhesion, going beyond other nanotechnological solutions on the market.