Toran 3®: pretreatment alternative to phospho-degreasing or passivating processes

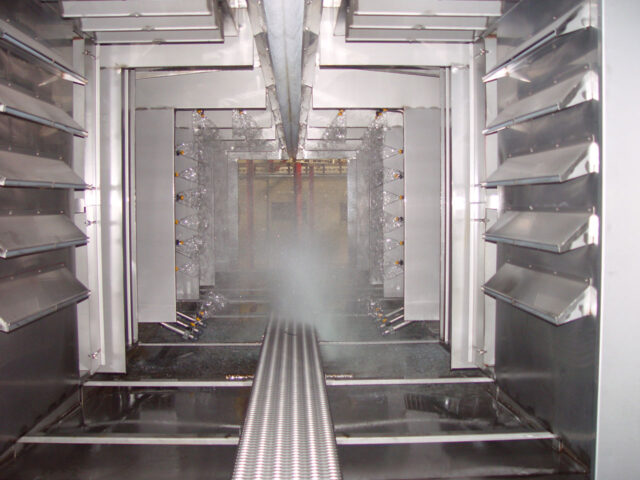

Toran 3®: the single-stage pretreatment technology, developed to prepare metallic surfaces for coating.

Chemtec’s innovative and environmentally friendly single-stage room temperature pretreatment technology, developed to prepare metallic surfaces for coating.

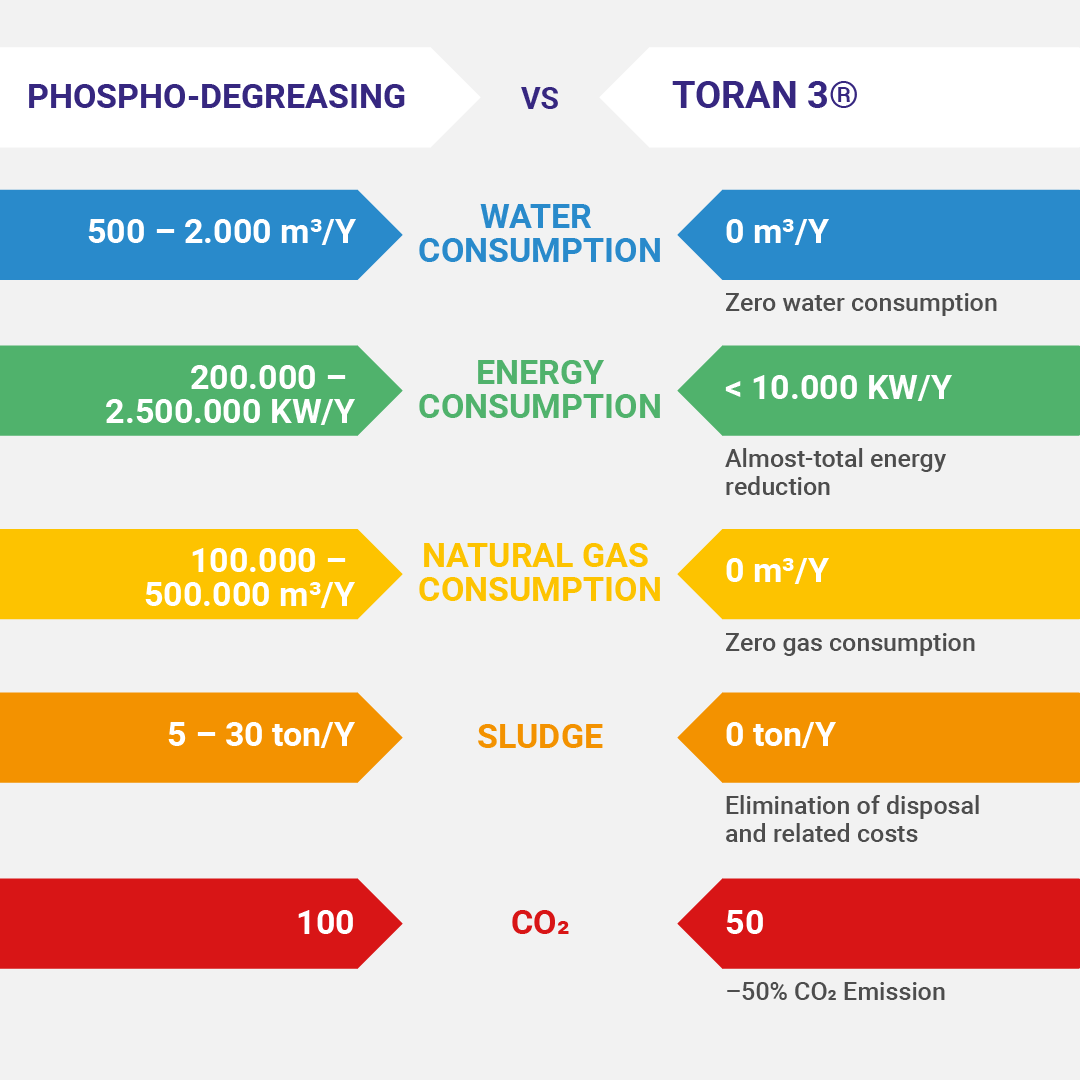

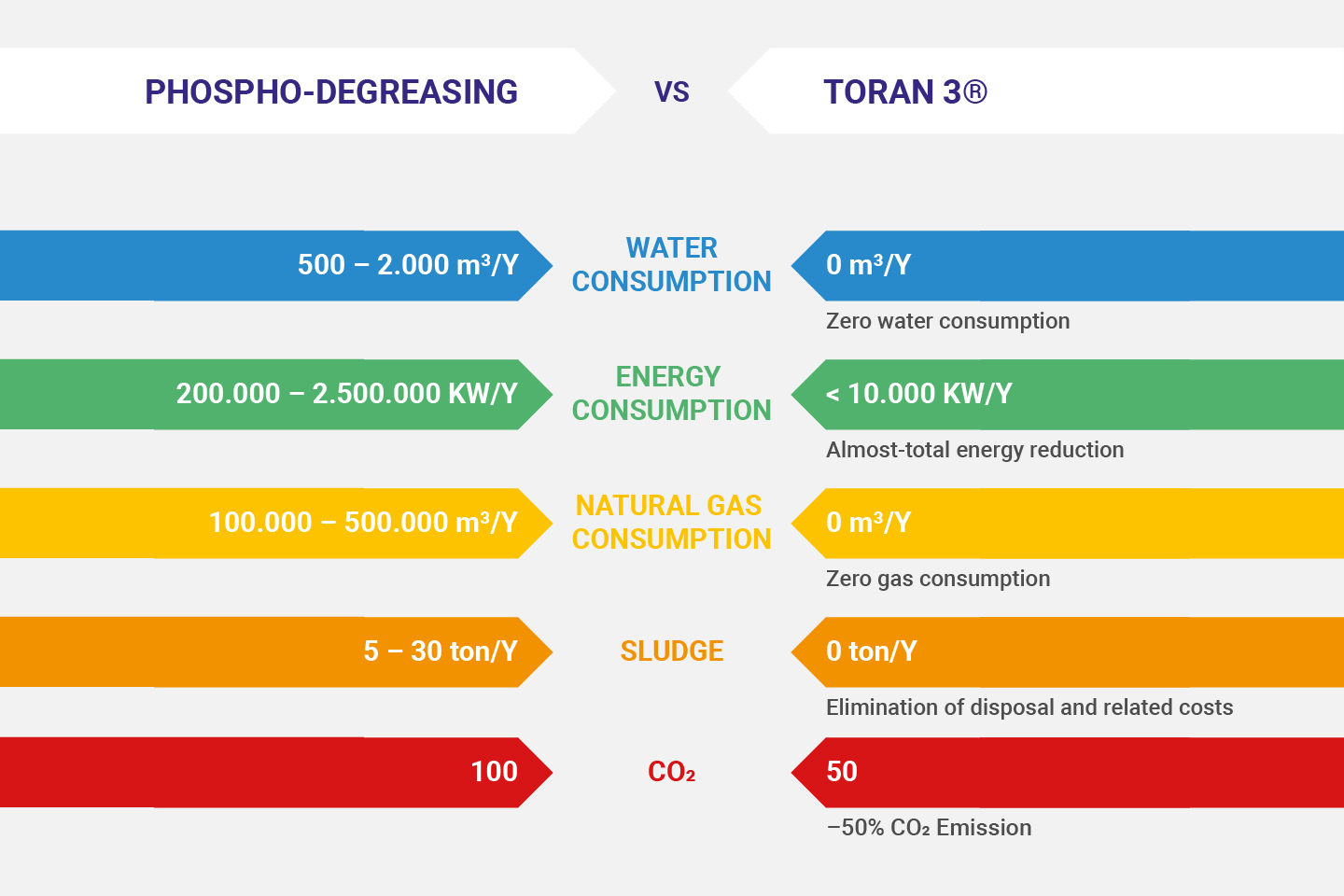

With no rinsing or degreasing required and no sludge or waste byproducts to dispose of, our anhydrous process is based on high-boiling organic fluids for effective degreasing and immediate protection against oxidation. This system provides a valid and cost-effective alternative to phospho-degreasing or passivating processes.